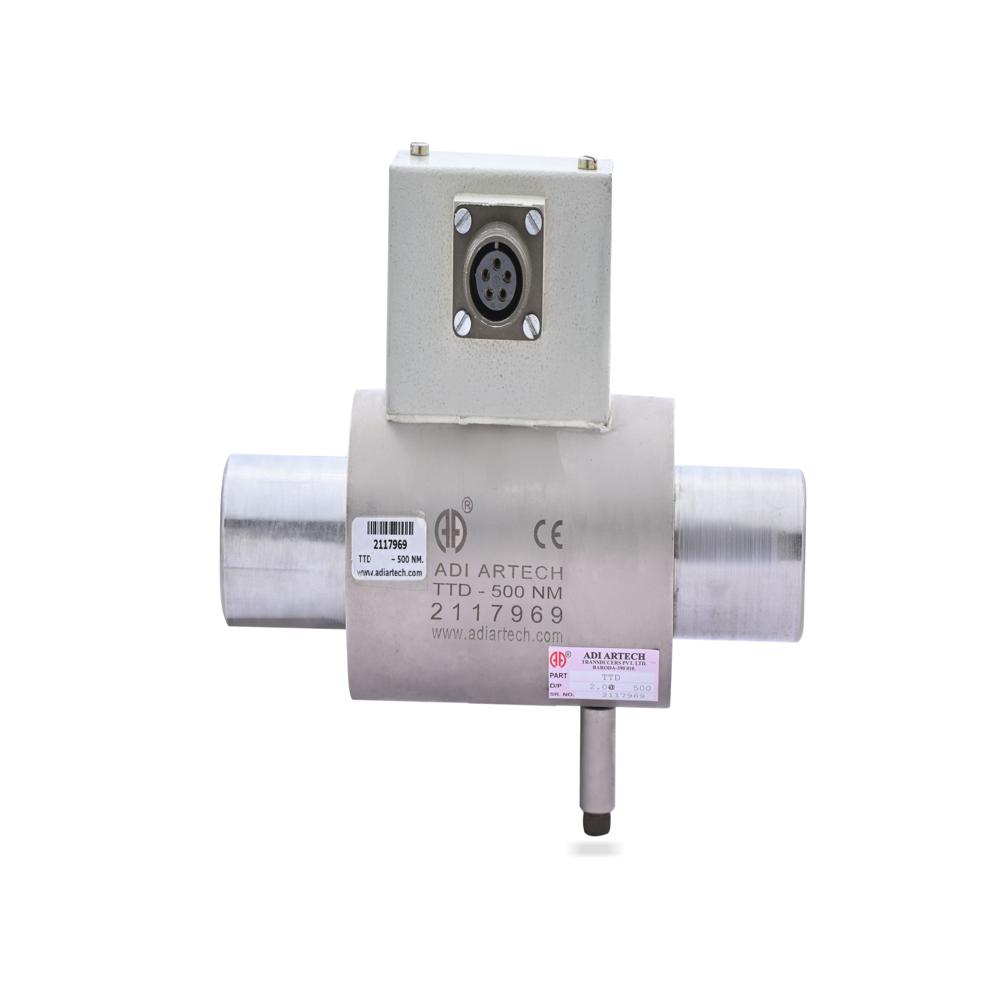

Dynamic type Rotary Torque Transduser Flange Type

Product Details:

- Resistance 350

- Output Analog

- Theory Strain Gauge Type

- Type Rotary Torque Transducer

- Accuracy 0.1% F.S.

- Operating Voltage 5-15 V DC

- Output Voltage 1.0 mV/V (0.1 mV/V)

- Click to view more

Dynamic type Rotary Torque Transduser Flange Type Price And Quantity

- 90000.0 INR/Number

- 1 Number

- Alloy Steel/Aluminum

- 5 meters (standard)

- 10 Nm to 2000 Nm

- Up to 3 kHz

- 150% of F.S.

- Circular, 5-pin

- IP65

- Laboratory, Industrial Automation, Test Benches

- ±1% of F.S.

- Non-contact (Optional)

- Flange

Dynamic type Rotary Torque Transduser Flange Type Product Specifications

- 350

- -10C to +50C

- Analog

- 1.0 mV/V (0.1 mV/V)

- -20C to +80C

- Strain Gauge Type

- -10C to +60C

- Rotary Torque Transducer

- 0.1% F.S.

- 5-15 V DC

- Alloy Steel/Aluminum

- 5 meters (standard)

- 10 Nm to 2000 Nm

- Up to 3 kHz

- 150% of F.S.

- Circular, 5-pin

- IP65

- Laboratory, Industrial Automation, Test Benches

- ±1% of F.S.

- Non-contact (Optional)

- Flange

Dynamic type Rotary Torque Transduser Flange Type Trade Information

- 10 Number Per Week

- 1 Week

- Western Europe, Middle East, Africa, Asia, Eastern Europe

- All India

Product Description

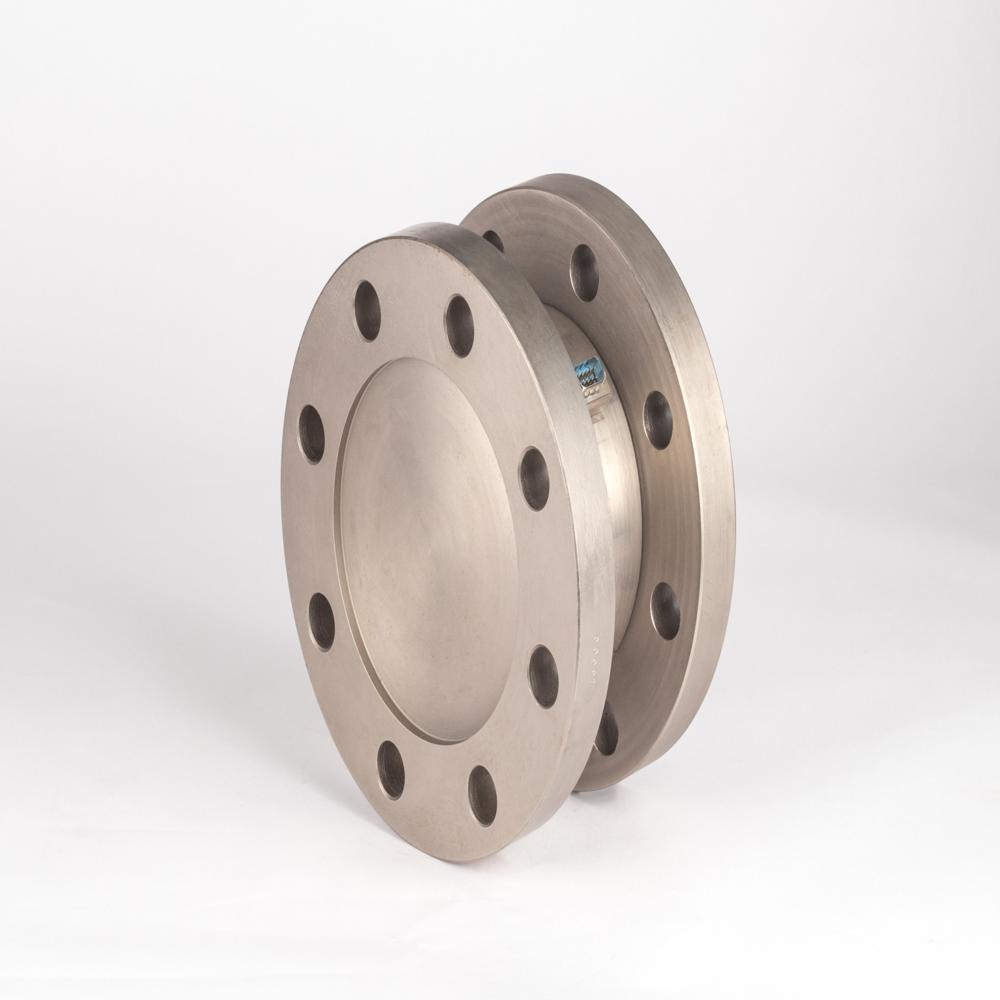

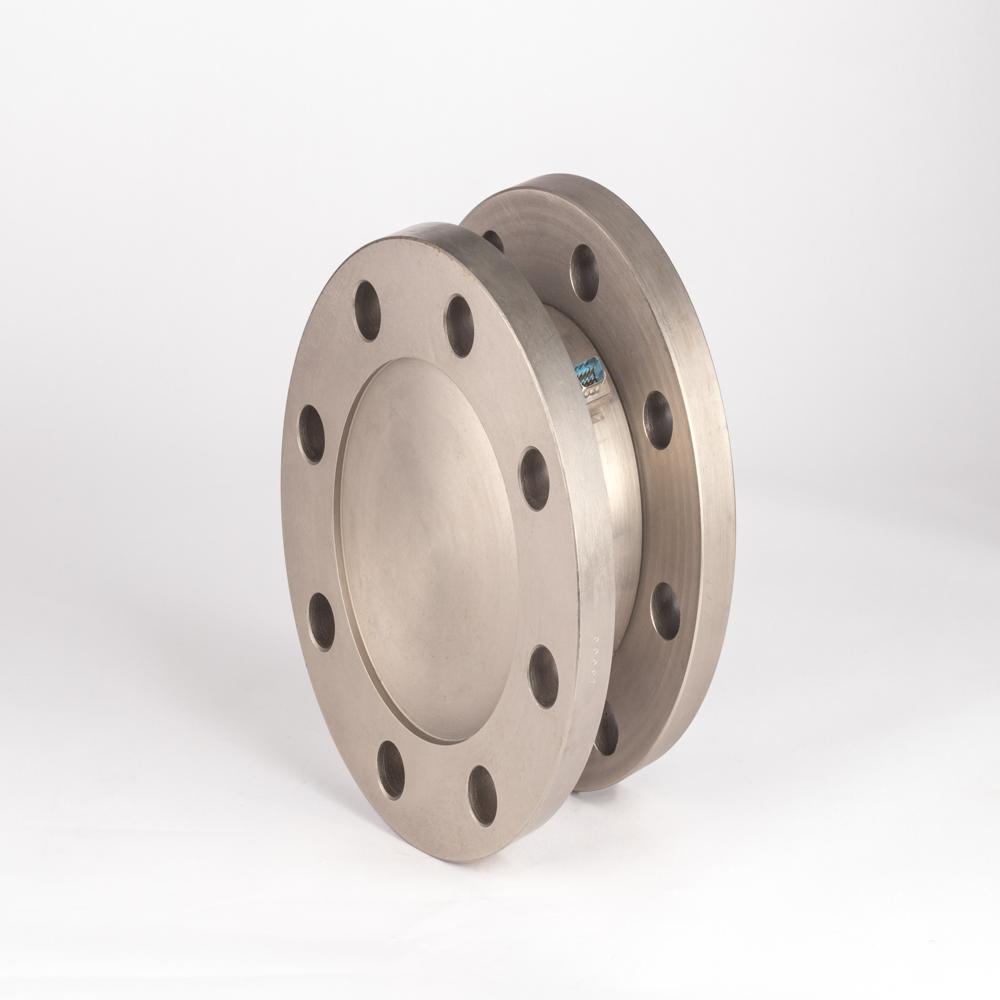

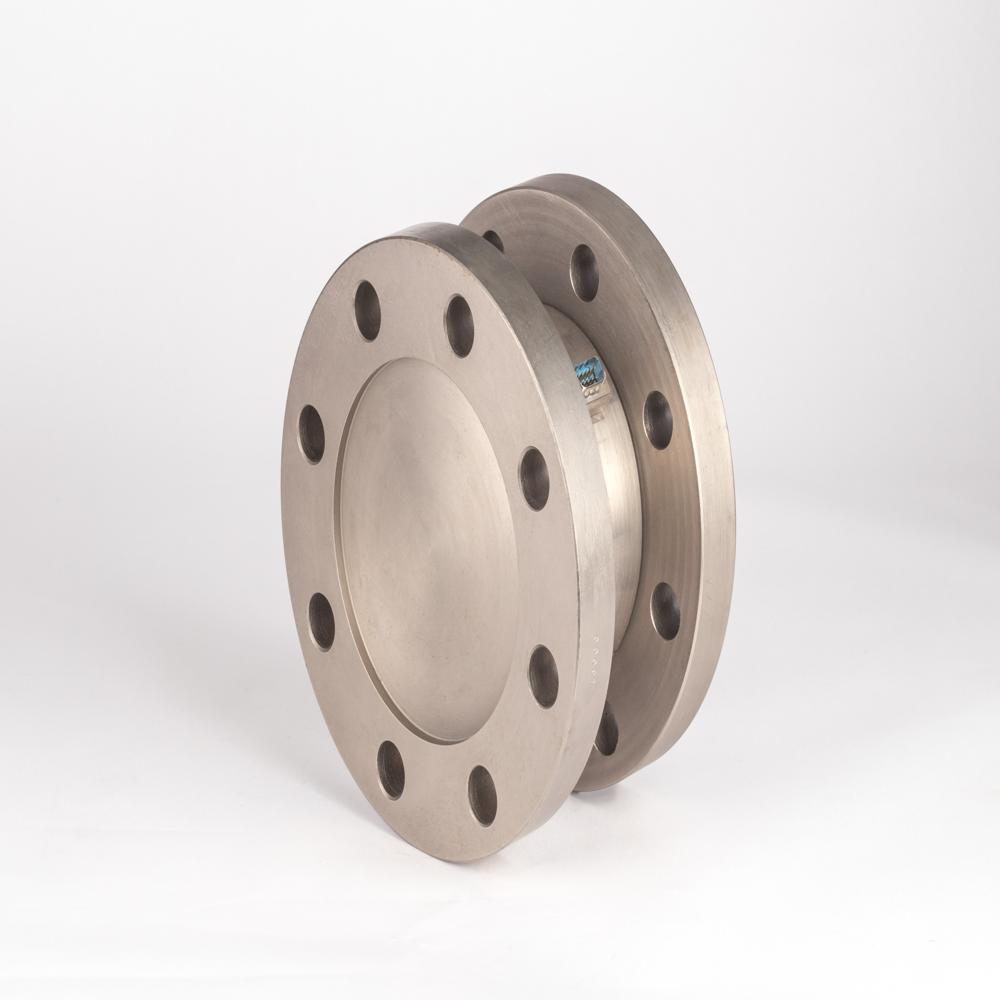

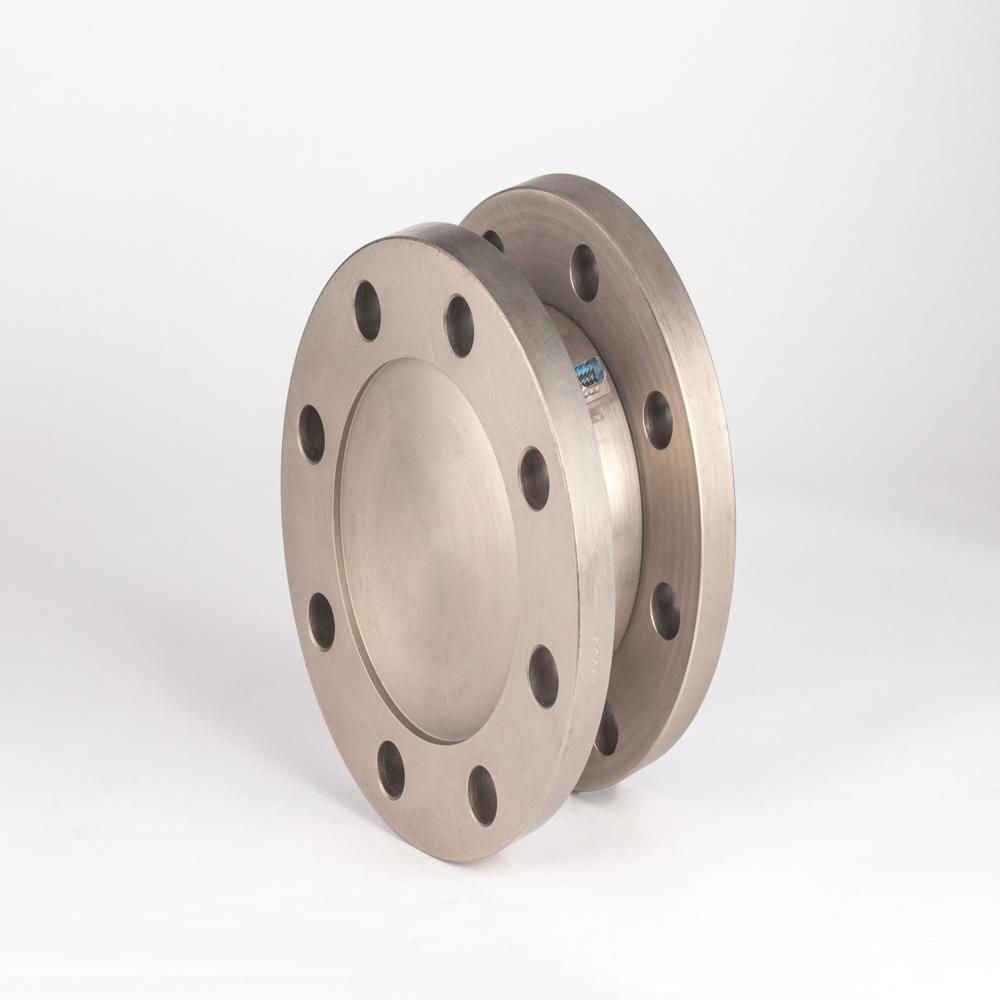

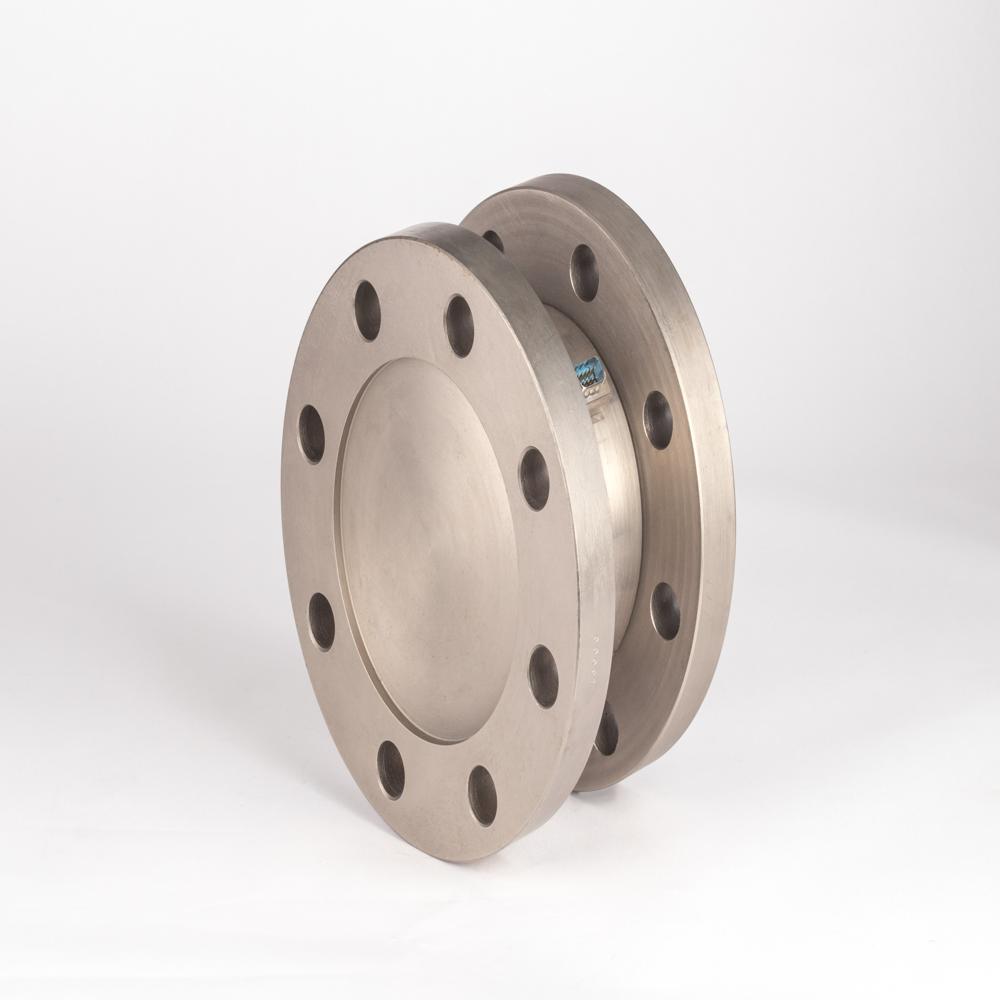

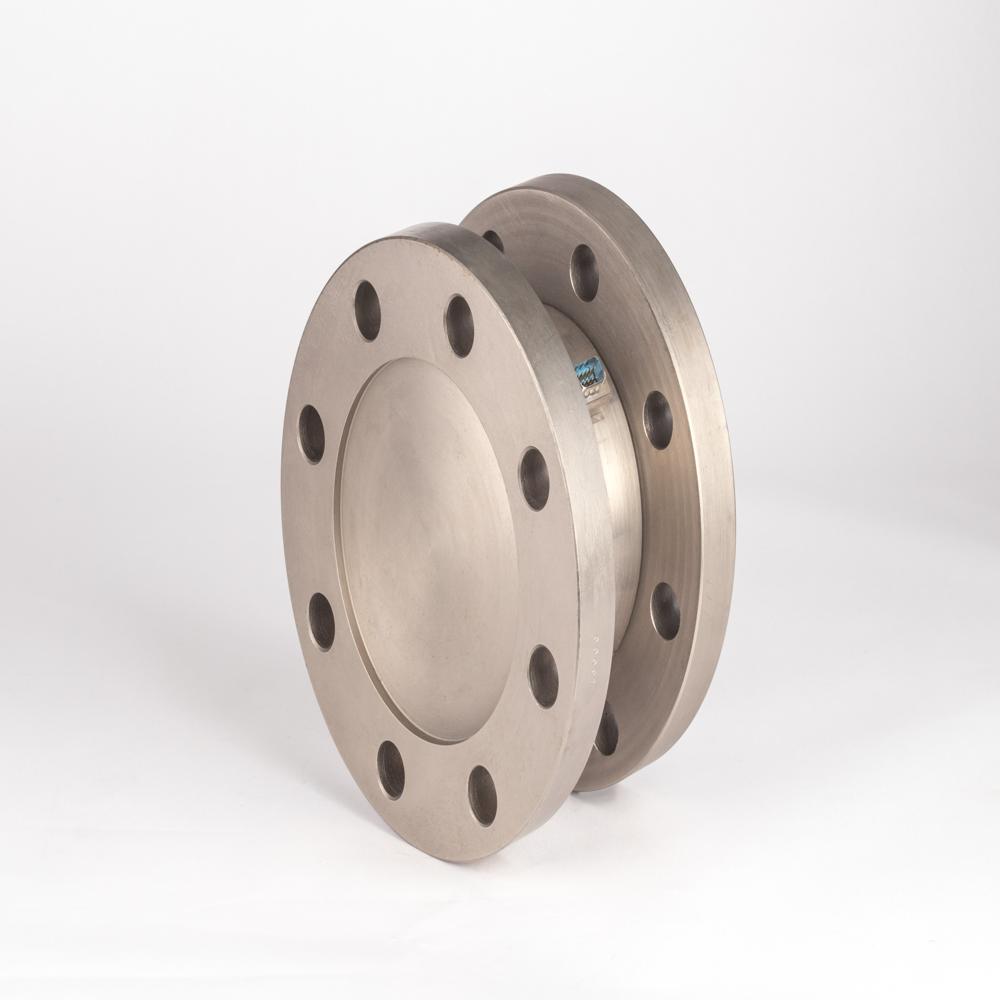

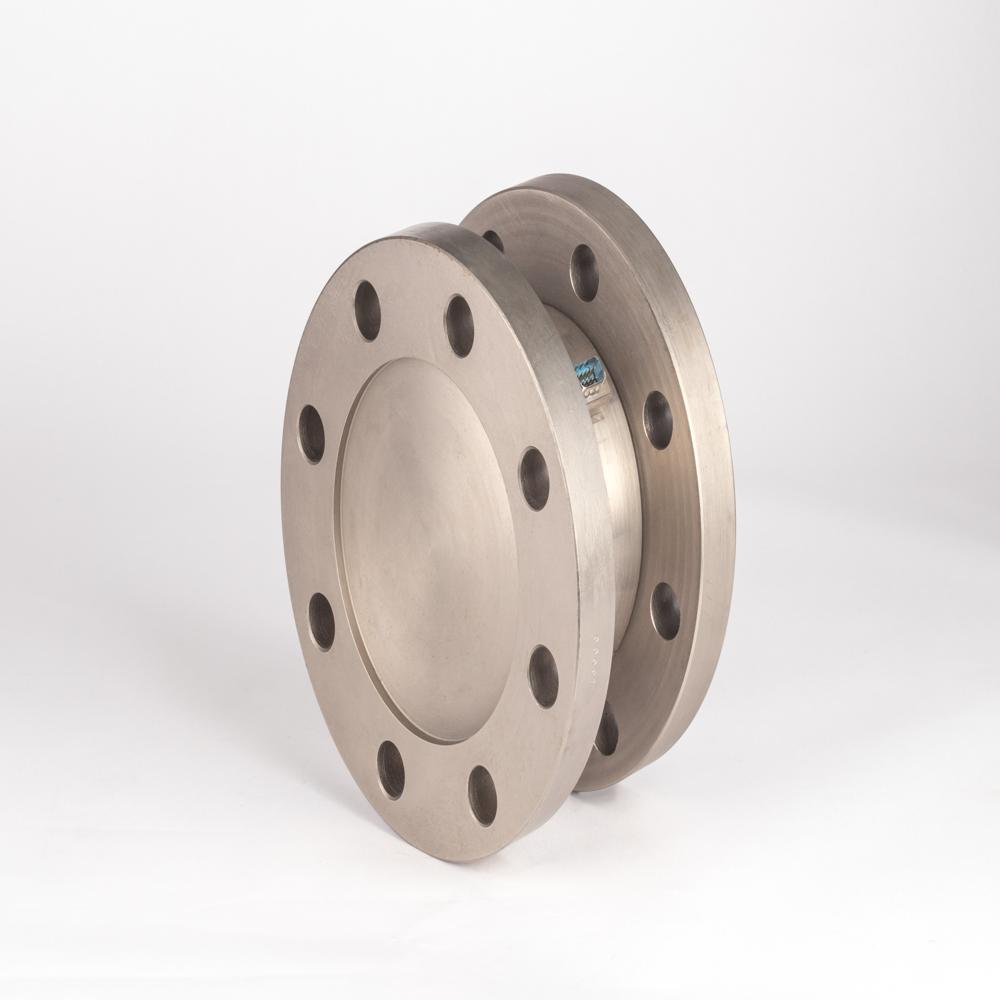

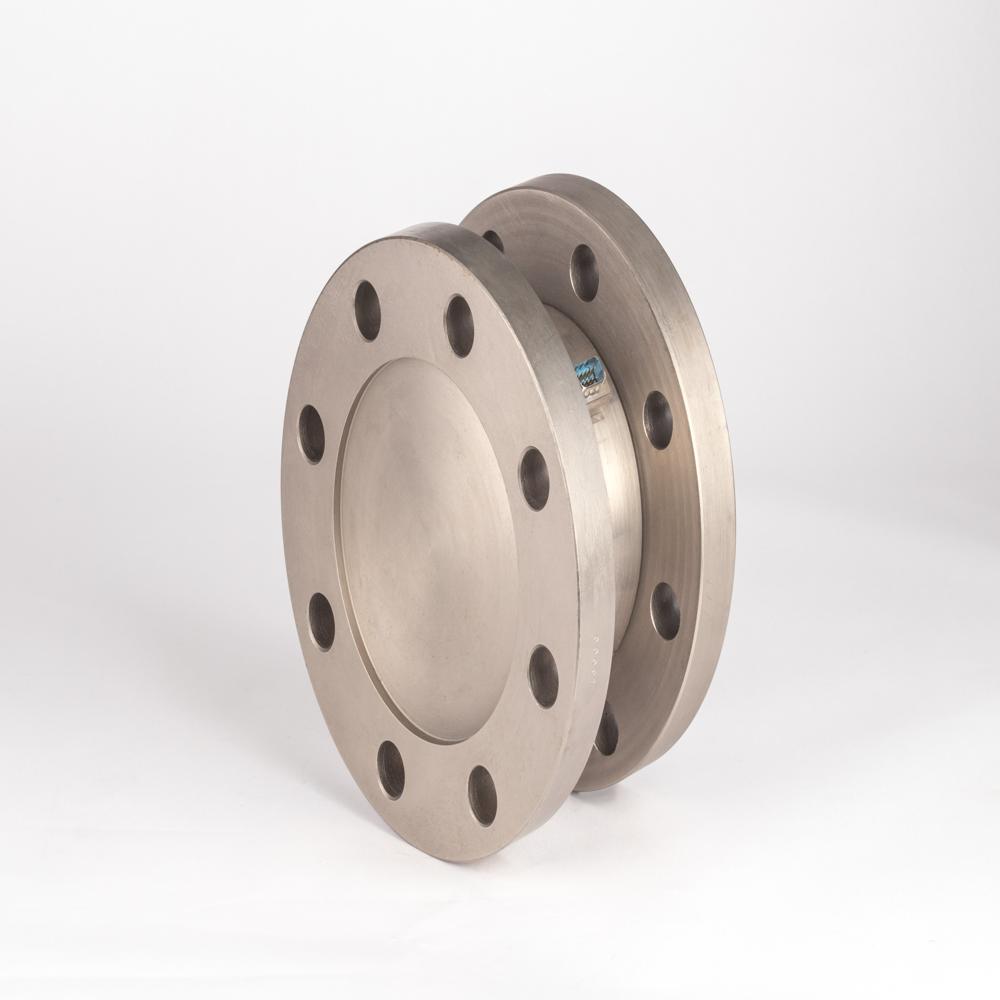

Dynamic type Rotary Torque Transducer Flange Type

|

Model |

: | TTD-FF | |

| Capacity | : | 0 - 50 NM to 0 - 50000 NM | |

| Load Direction | : | Clock & Anticlock Wise | |

| Type | : | Torque Sensor / Transducer - Flange to Flange - Dynamic |

| Industries |

|

|

| Application |

|

|

| Description | : |

Flange to Flange Dynamic Slip ring Torque Transducer is general purpose sensor for accurate measurement of torque in rotating shaft or equipment. |

| Features | : |

0 - 50 NM to 0 - 50,000 NM range is offered. |

| Electronic Instrumentation / Software | : |

Compatible Electronic Systems are available optionally- |

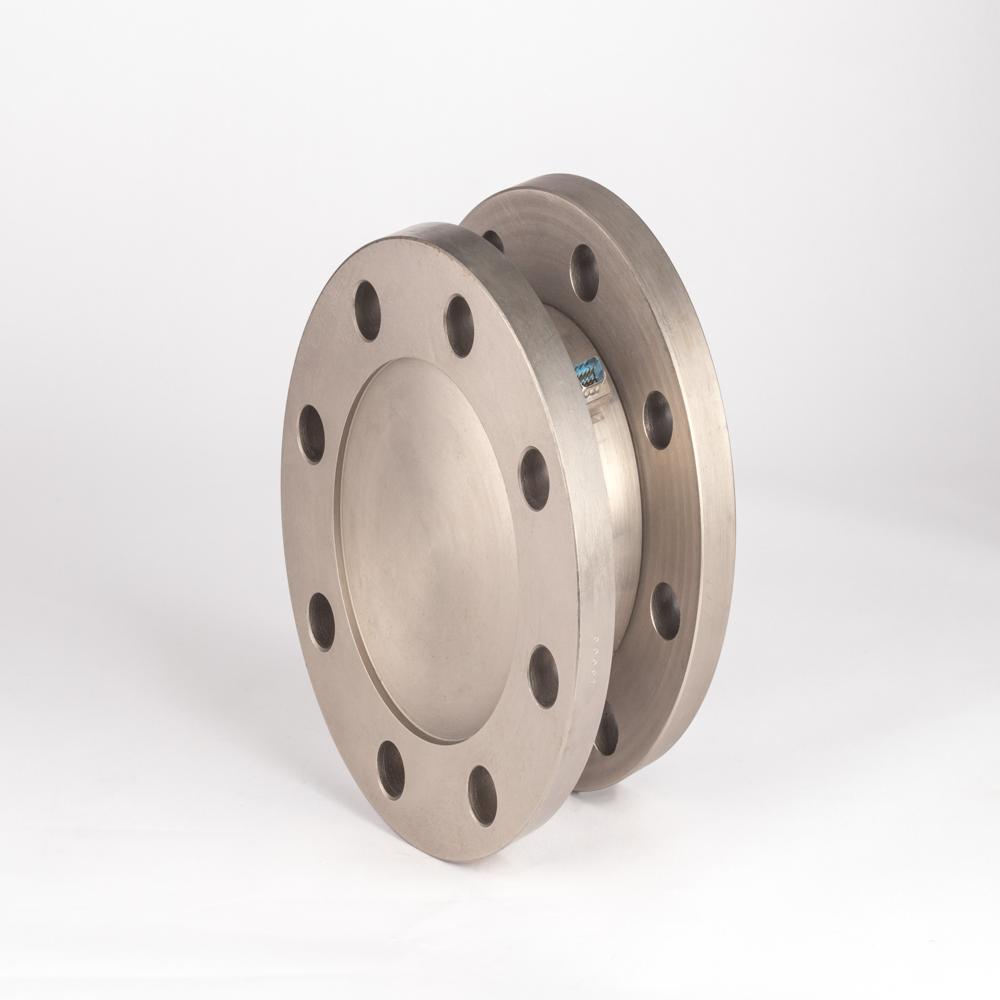

Unmatched Versatility for Dynamic Torque Measurement

This rotary torque transducer is engineered for versatility, serving across laboratories, industrial automation, and rigorous test benches. Its broad measuring range and robust build in alloy steel or aluminum ensure reliable performance even under fluctuating operational demands. The flange mounting provides secure installation, making the transducer adaptable to various mechanical setups for seamless torque measurement.

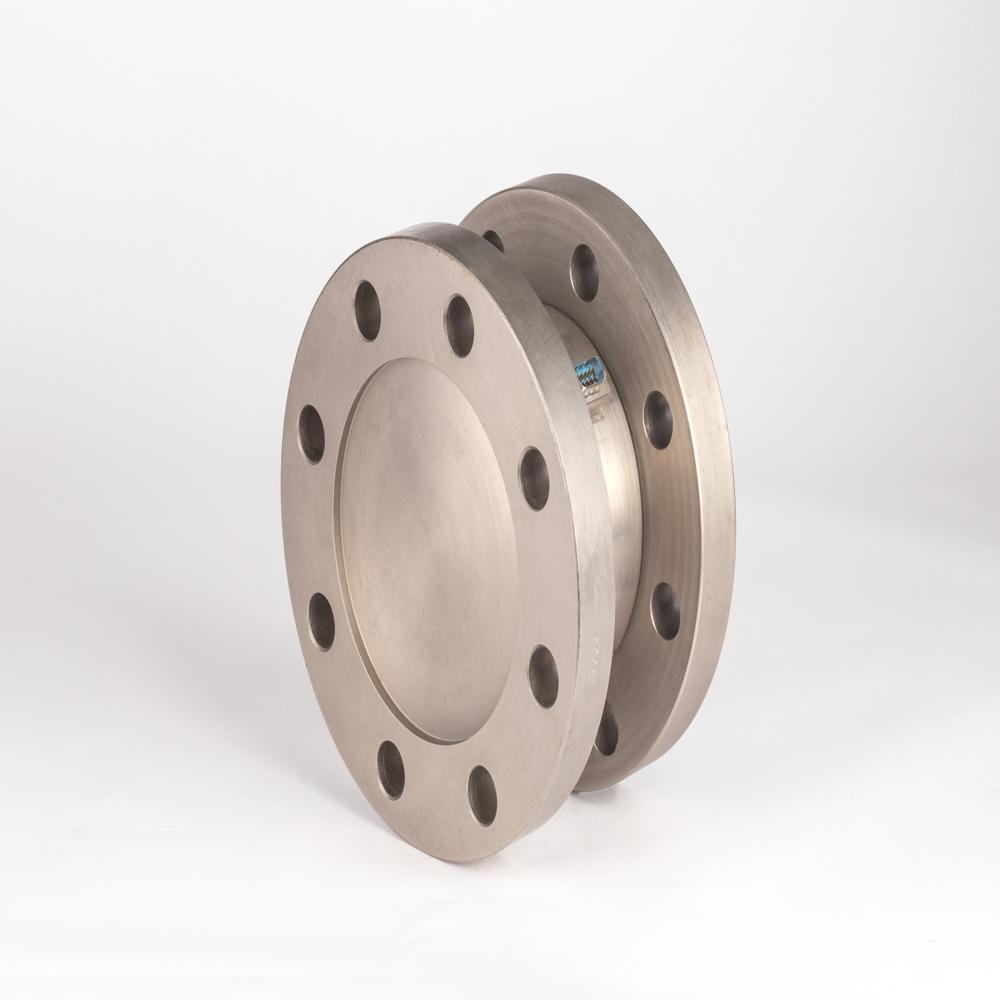

Advanced Accuracy and Speed

Expect remarkable precision with an accuracy of 0.1% F.S. and a response frequency reaching up to 3 kHz. The devices strain gauge technology and carefully balanced design (1% F.S.) allow for accurate and real-time torque measurement, capturing even rapid changes without loss of data integrity. This makes it the preferred choice for applications that demand both high fidelity and speed.

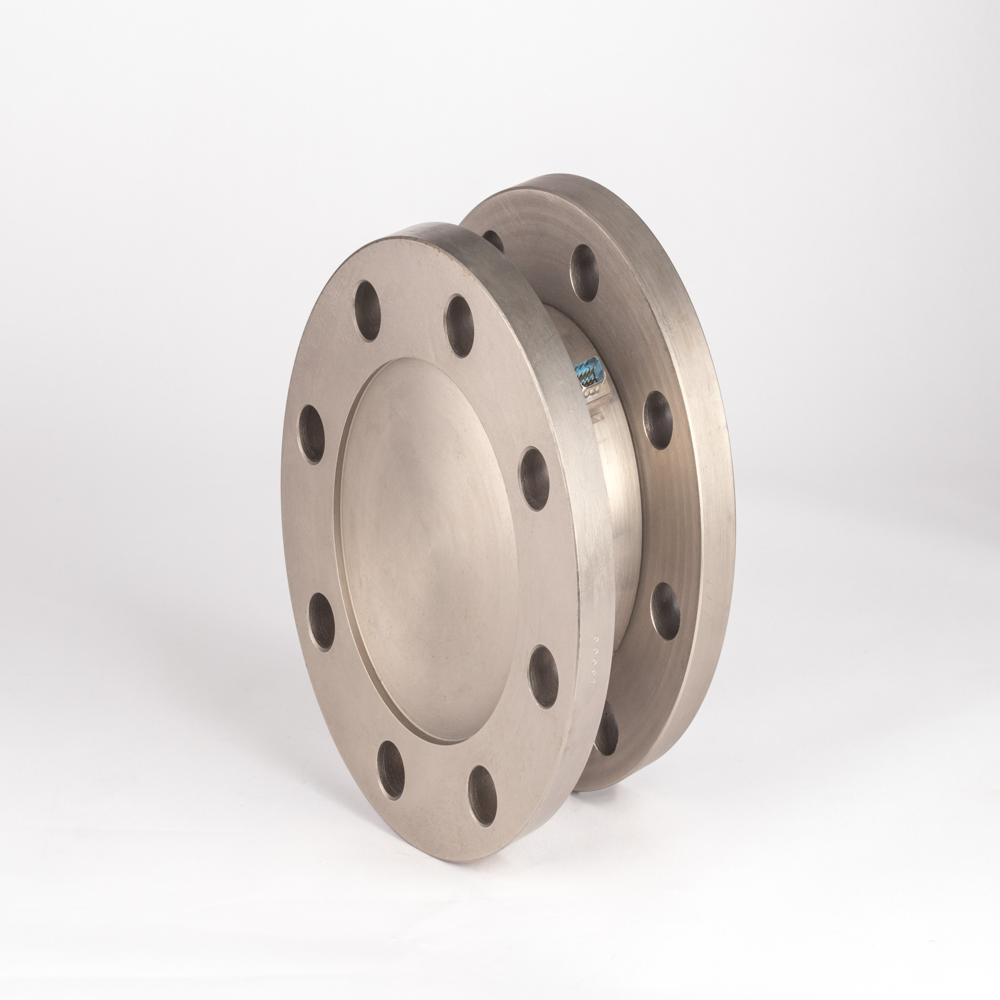

Reliable, Efficient Transmission and Protection

Equipped with IP65 protection, this torque transducer resists dust and water ingress, extending its lifespan in demanding environments. The optional non-contact signal transmission ensures minimal wear and maximum reliability, while the standard 5-meter cable and robust circular 5-pin connector facilitate hassle-free integration. Its smart overload capacity protects against accidental overloads, adding another layer of operational safety.

FAQs of Dynamic type Rotary Torque Transduser Flange Type:

Q: How is the rotary torque transducer typically used in laboratory and industrial automation environments?

A: The transducer is fitted to rotary equipment via its flange mount to measure real-time torque. In laboratory and industrial contexts, it monitors torque output for quality assurance, research, and automation processes, ensuring machinery operates within specified limits and facilitating performance analysis.Q: What are the benefits of the non-contact signal transmission option available for this torque transducer?

A: The non-contact signal transmission option eliminates physical connection wear and reduces maintenance, enhancing reliability for continuous, high-speed measurements in dynamic applications.Q: When should I use the overload protection feature of the transducer?

A: The built-in overload protection feature should be relied upon when theres a risk of sudden torque spikes, as it can handle overloads up to 150% of its rated capacity. This protects the sensor from damage during unexpected operating conditions.Q: Where can this torque transducer be installed, considering its environmental resilience?

A: With an IP65 protection rating and a wide operating temperature range (-10C to +60C), the transducer is suitable for installation in both indoor laboratories and industrial settings exposed to moderate dust, moisture, and temperature variations.Q: What process does the sensor use to measure torque, and what output does it generate?

A: The device employs strain gauge technology for precise torque measurement and generates a high-accuracy analog output voltage of 1.0 mV/V (0.1 mV/V), enabling seamless interfacing with data acquisition systems and monitoring instruments.Q: How does the flange mounting ensure secure installation?

A: The flange mounting system provides a stable and secure attachment point to rotating shafts or machinery, minimizing vibration and movement, which translates to more consistent and reliable torque measurement results.Q: What is the advantage of the provided 5-meter cable and circular 5-pin connector?

A: The standard 5-meter cable and circular 5-pin connector allow for flexible installation and quick, secure connections, accommodating diverse setup requirements and simplifying integration with various data systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'REACTION AND ROTARY TORQUE TRANSDUCERS' category

|

ADI ARTECH TRANSDUCERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |