Load Cell , Instrument , Assembly and Software

Product Details:

- Resistance 350

- Output Analog

- Theory Resistance Strain

- Type S Type

- Accuracy 0.03% F.S.

- Operating Voltage 5V to 12V DC

- Output Voltage 1.5mV/V to 3.0mV/V

- Click to view more

Load Cell , Instrument , Assembly and Software Price And Quantity

- 1 Set

Load Cell , Instrument , Assembly and Software Product Specifications

- 5V to 12V DC

- -20C to +65C

- Resistance Strain

- Analog

- 1.5mV/V to 3.0mV/V

- 0.03% F.S.

- S Type

- 350

- -10C to +55C

- -10C to +40C

Load Cell , Instrument , Assembly and Software Trade Information

- 10 Set Per Week

- 1 Week

- Eastern Europe, Western Europe, Middle East, Asia, Africa

- All India

Product Description

Load Cell , Instrument , Assembly and Software

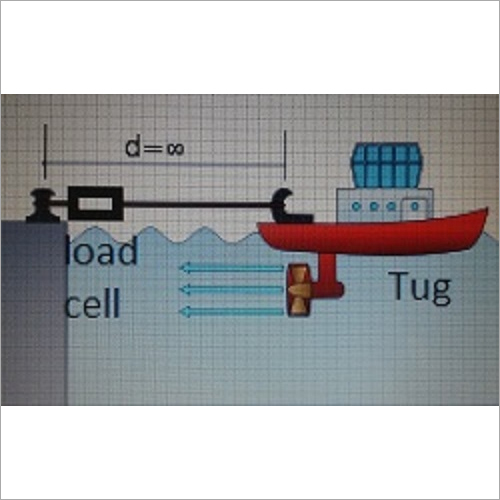

Bollard pull is the pulling/tractive force of the ship/tug exerted on another ship or an object on the shore.

It is measured in unit Newton or Tonnes.

Horsepower of the ship/tug is not significant because of factors like transmission losses, propulsion type and its efficiency etc. Hence the pulling force of the ship/tug is measured for finding the strength.

Bollard Pull test is conducted to determine the static pull that a tug / ship is capable of exerting under practical operating conditions with its own propulsion system. The test is performed by tying a hawser from ship to a fixed bollard at shore and measure the pull of the ship in Newton or Tonnes under maximum operating conditions by means of a Load cell, indicator-Dynamometer arranged between the hawser and bollard.

All the newly- constructed tugs and special offshore ships like Anchor handling Tug supply vessels need to carry out this test prior to delivery in presence of ship owners and classification agency for practically proving its pulling power.

Further, existing ships after undergoing extensive repairs have to undergo this test.

This pull test certifies how healthy is the ship/tug.

This is carried out by the force measuring dynamometer comprised of Load cell , Load indicator.

Load cell is the force measuring link and it is made as a part of the rope that ties the bollard on the shore and ships towing hook.

The ideal conditions for this test are-

Deep and calm water

Ship away from the shore

Calm weather

Bollard and the towing hook should be at the same height

Adi Artech can support this application with-

Load Cell Model 20410 1 no.

Digital Load Indicator 1 no.

Suitable shackles - one pair of two pcs.

Load cell capacity is available from 2 Tf to 300 Tf.

One can select suitable capacity and its matching indicator.

Exceptional Performance and Versatility

This load cell system stands out with its broad capacity range, durable alloy steel or stainless steel design, and high accuracy. Its S Type resistance strain technology ensures reliable output even in tough environments, making it desirable for manufacturers, exporters, and trade professionals in India.

Advanced Instrument and Software Integration

Equipped with a digital or LCD instrument display, the system facilitates effortless data readings. The user-friendly software provides real-time data acquisition and calibration, enabling seamless process monitoring and efficient quality control in industrial settings.

Comprehensive Assembly and Connectivity

Assembly options include single or multi-channel configurations to suit diverse weighing requirements. With a 2m waterproof shielded cable and plug connection, alongside fast response and superior insulation resistance, this system ensures stable and secure performance in various installations.

FAQs of Load Cell , Instrument , Assembly and Software:

Q: How can I integrate the load cell assembly into my weighing system?

A: Integration is straightforward: install the S Type load cell mechanically between the mounting points, connect the shielded cables waterproof plug to your instrument, and configure the software for real-time data acquisition. Choose single or multi-channel assembly based on your applications scale.Q: What are the main benefits of using this load cell and software package?

A: The system delivers high accuracy (0.03% F.S.), fast response (<1ms), and robust overload protection, ensuring precise and reliable measurements. Real-time data acquisition and ease of calibration streamline your weighing processes, enhancing productivity and quality assurance.Q: Where can this load cell system be used effectively?

A: It is suitable for industrial and commercial environments, including manufacturing, logistics, food processing, and laboratory settings. The robust materials and IP65 protection make it ideal for demanding applications across India.Q: When should calibration be performed on the load cell system?

A: Calibration is recommended upon installation, after system modifications, or routinely as part of quality control. The included software simplifies the calibration process for both initial setup and regular maintenance.Q: What process is involved in data acquisition and analysis?

A: Once installed, the software captures live measurement data from the instruments digital/LCD display, allowing for real-time monitoring and quick calibration adjustments. This process improves traceability and facilitates robust reporting.Q: How does the system ensure safe operation and prevent damage?

A: The assembly supports usage up to 120% safe overload and 150% overload limit, safeguarding the load cell against excessive loads. Waterproof connectors, shielded cabling, and IP65-rated construction further enhance operational safety.Q: What are the usage advantages for dealers, suppliers, and exporters in India?

A: Dealers and exporters benefit from a versatile, reliable product that meets industry standards and caters to a wide market. Its easy installation, real-time data access, and robust performance make it an attractive choice for distribution across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Tension Force Sensor' category

|

ADI ARTECH TRANSDUCERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |