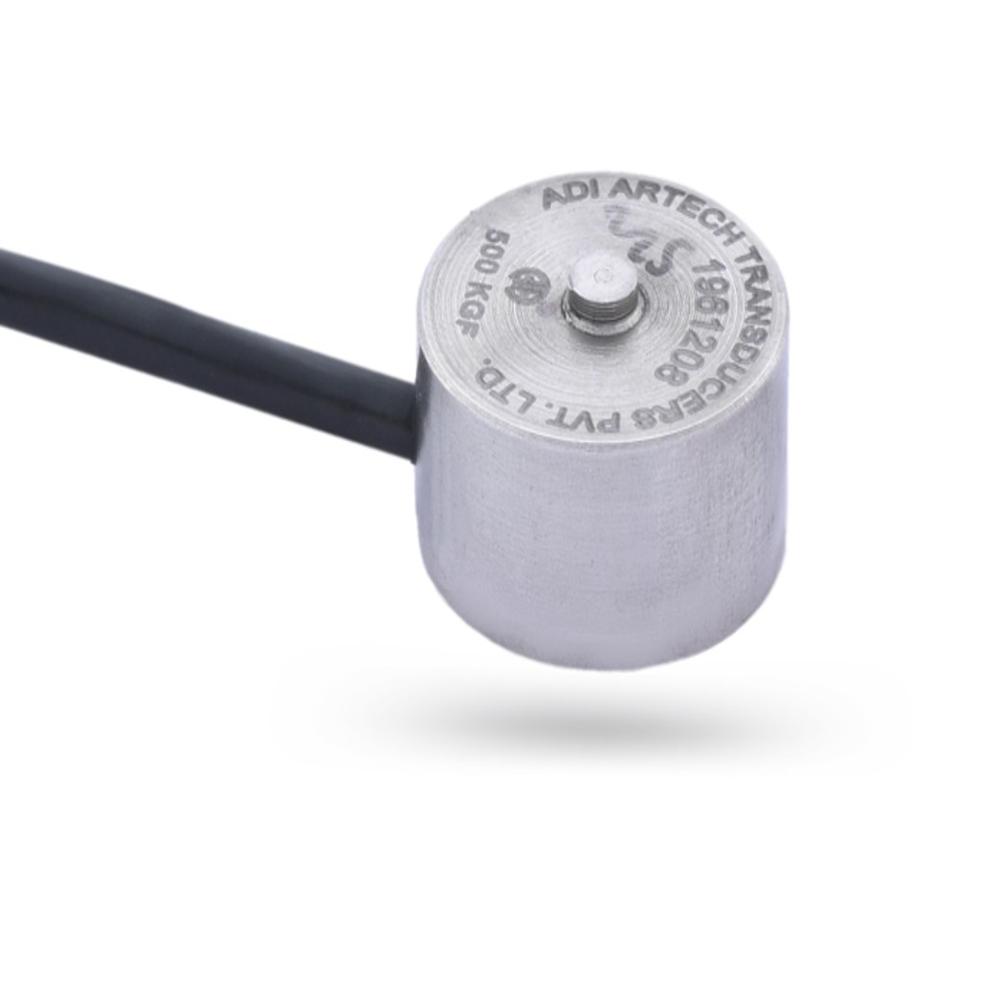

Mini Pancake Load Cell with Threaded loading Button

15500.0 INR/Number

Product Details:

- Application Tension / Compression Testing, Force & Impact Testing, Robotics , Pharma Machinery ,Test Bench Automation , Spring Testing Machine, Pharmacy Machines

- Product Type from given pdf filr i need below point; Product type: Classification: Power: Voltage: Mterial: operate method: Accuracy: Type: Theory: Output: operating temperature: compensated temperature: Operating voltage: storage temoerature: output voltage: resistance: usage: Application: capacity

- Power 10 VDC Volt (v)

- Weight 500 Grams (g)

- Material Aluminum Alloy (10, 20 Kgf), Stainless Steel 17-4 PH (50, 100 Kgf)

- Capacity 10, 20, 50, 100, 200, 500, 1000, 1500 Kg

- Usage Force measurement where space is constrained

- Click to view more

X

Mini Pancake Load Cell with Threaded loading Button Price And Quantity

- 1 Number

- 15500.0 INR/Number

- 10 kg to 500 kg

- IP66

- 200% of Rated Capacity

- Stainless Steel

- 150% of Rated Capacity

- M6x1, M8x1.25 (varies by model)

- Center hole with threaded loading button

- Robotics, Automation, Weighing Systems, Material Testing

- Diameter: 40mm, Height: 15mm (typical)

- 2 meters (standard)

Mini Pancake Load Cell with Threaded loading Button Product Specifications

- 500 Grams (g)

- 10 VDC Volt (v)

- from given pdf filr i need below point; Product type: Classification: Power: Voltage: Mterial: operate method: Accuracy: Type: Theory: Output: operating temperature: compensated temperature: Operating voltage: storage temoerature: output voltage: resistance: usage: Application: capacity

- 20 C to 50 C Celsius (oC)

- Resistance Sensor

- 10 VDC (Maximum 15 VDC) Volt (v)

- 10 C to 50 C Celsius (oC)

- Strain Gauge Based Compression Load Cell

- Analog Sensor

- 0.25% FSO %

- Aluminum Alloy (10, 20 Kgf), Stainless Steel 17-4 PH (50, 100 Kgf)

- 1.50 mV/V 0.5 Volt (V)

- Mini Pancake Load Cell with Threaded loading Button

- Force measurement where space is constrained

- 10, 20, 50, 100, 200, 500, 1000, 1500 Kg

- Tension / Compression Testing, Force & Impact Testing, Robotics , Pharma Machinery ,Test Bench Automation , Spring Testing Machine, Pharmacy Machines

- Input Resistance: 390 25 Ohms, Output Resistance: 350 3 Ohms

- Strain Gauge Based Compression Loading through Threaded Button

- 10 C to 50 C Celsius (oC)

- 5V to 12V DC Volt (V)

- 10 kg to 500 kg

- IP66

- 200% of Rated Capacity

- Stainless Steel

- 150% of Rated Capacity

- M6x1, M8x1.25 (varies by model)

- Center hole with threaded loading button

- Robotics, Automation, Weighing Systems, Material Testing

- Diameter: 40mm, Height: 15mm (typical)

- 2 meters (standard)

Mini Pancake Load Cell with Threaded loading Button Trade Information

- VADODARA

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Number Per Week

- 1 Week

- Yes

- Asia, Eastern Europe, Western Europe, Middle East, Africa

- All India

- OEM TEST CERTIFICATE

Product Description

Mini Pancake Load Cell With Threaded Loading Button

Model: 90610-Mt-Threaded Button

Capacity: 0-10Kgf To 0-1500Kgf

Type: Pancake Load Cell

Industries

- Testing Machinery's

- Robotics

- R & D Establishments

- Pharmaceutical

-

Medical & Health Care

-

Material Testing

-

Manufacturing

-

Automotive

-

Automation Machinery's

Application

- Compressive Force Measurement & Testing

- Force & Impact Testing

- Force Gage

- Force In Product Testing

- Impact Measurement

- Machine Automation

- Pedal Force Monitor

- Tablet Hardness Testing Machine

- Tablet Manufacturing Machine

- Tensile Testing

Description

- 90610-Mt In Mini Pancake Load Cell.

- It Is Constructed From Aluminum Alloy For Light Weight.

- This Is Strain Gage Based With Temperature Compensation From 0 To 60 Deg.C.

Features

- 90610-Mt In Mini Pancake Load Cell.

- It Is Specially Designed To Suit Tablet Hardness Testing Machine With Threaded Loading Bottom.

- This Can Be Customized To Suit Customers Dimensions And Capacity.

- Electronic Instrumentation / Software :

Compatible Electronic Systems Are Available Optionally-

Stand Alone Digital Display Indicator.

Analog Signal Converter - 0 - 10 Vdc Or 4 - 20 Ma For Plc Interface.

Digital Signal Converter - Rs-232 , Rs-485 Or Mod bus Rtu Protocol To Interface With Computer Or Other Processing Equipment.

Data Acquisition System And Software.

For More Details,Please Contact Us.

Precision Measurement and Durable Construction

Fabricated from stainless steel, the Mini Pancake Load Cell delivers robust performance, achieving accurate measurements with a nominal output of 1.0mV/V. Its low-profile, center-hole design with a threaded loading button ensures stable mounting and force transmission, vital for consistent results in automation, weighing, and materials research.

Versatile Application and Reliable Protection

With a standard IP66 rating, this load cell withstands challenging industrial environments. Wide temperature tolerance and safe/ultimate overload protections enable secure, extended operation across diverse applications, from robotics to material testing, while the choice of M6x1 or M8x1.25 thread sizes allows easy integration.

FAQs of Mini Pancake Load Cell with Threaded loading Button:

Q: How do I install the Mini Pancake Load Cell with a threaded loading button?

A: Begin by positioning the load cell onto the mounting surface, aligning the center hole. Secure the unit using the appropriate threaded loading button (M6x1 or M8x1.25, depending on your model). Ensure the load is applied vertically through the center, avoiding any side loads that could impact accuracy.Q: What types of applications can benefit from this load cell?

A: This load cell is ideal for use in robotics, automation systems, weighing platforms, and material testing setups. Its robust build, high accuracy, and compact size make it suitable for integration where space is limited and precision force measurement is crucial.Q: When should I consider using a load cell with a 150% safe and 200% ultimate overload rating?

A: Choose this load cell when your application may involve occasional force spikes or overloads. The 150% safe and 200% ultimate overload ratings provide a safety margin, reducing the risk of sensor damage and ensuring reliable performance in dynamic or unpredictable load conditions.Q: Where is the best placement for the load cell cable and why is a 2-meter length standard?

A: The cable should be routed along a protected path, away from sources of electromagnetic interference and mechanical abrasion. The standard 2-meter length provides flexibility for installation in most setups, allowing for effective signal transmission to measurement or control equipment.Q: What is the theory behind its operation and what output does it provide?

A: This load cell operates based on strain gauge technology, detecting minute deformations caused by applied forces. It outputs an analog voltage signal proportional to the load (1.0mV/V nominal), ensuring straightforward integration with standard measurement systems.Q: How does the IP66 protection class benefit industrial users?

A: IP66 protection ensures the load cell is completely dust-tight and protected against high-pressure water jets. This makes it resistant to harsh industrial environments, helping to prevent damage and maintain measurement reliability.Q: What are the advantages of choosing a stainless steel construction for a load cell?

A: Stainless steel provides excellent corrosion resistance, mechanical strength, and durability. This enhances the load cells lifespan, particularly in demanding or outdoor environments, ensuring consistent performance and reduced maintenance requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Low Profile Pancake Load Cell' category

|

ADI ARTECH TRANSDUCERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |