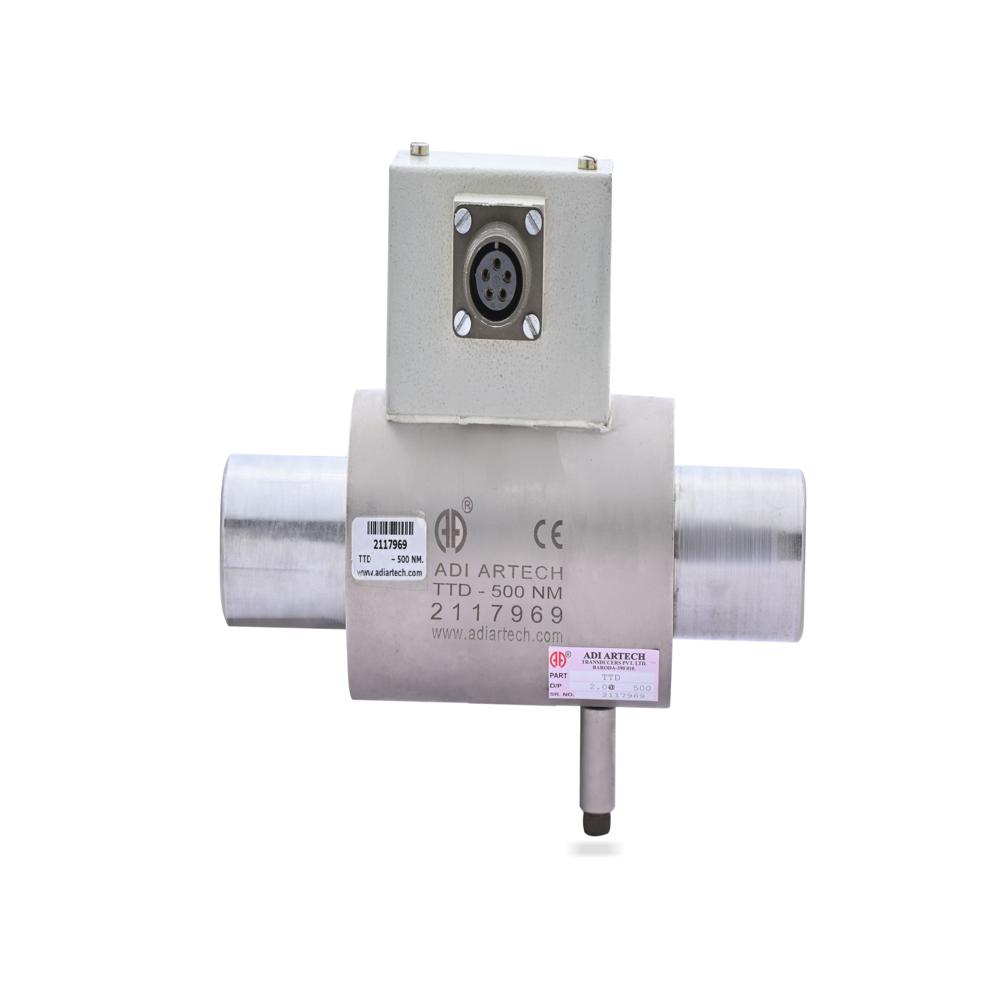

Static Torque Transducer Flange and Squre Drive Type

30000.0 INR/Number

Product Details:

- Product Type Static Reaction Torque Transducer

- Application Actuator / valve / electrical tool testing Axle & shaft torsion testing Bearing friction measurement Testing of motors, pumps, engines, brakes, clutches Automobile drivetrain & crankshaft torque testing Defense, Aerospace, R&D labs, Offshore test rigs, Machine tools, Electrical & Engineering industries

- Voltage 10 VDC (Maximum 15 VDC) Volt (v)

- Power 10 VDC Volt (v)

- Operate Method Static reaction torque measurement using strain gauges

- Classification Industrial & Research Grade

- Material Electroless Ni plated Tool Steel / Stainless Steel 17-4 PH

- Click to view more

X

Static Torque Transducer Flange and Squre Drive Type Price And Quantity

- 30000.0 INR/Number

- 1 Number

- Flange Mounted

- ±0.2% F.S.

- ±0.2% F.S.

- 10 Nm to 5000 Nm

- 2 meters (Standard)

- ±0.1% F.S.

- Flange & Square Drive

- ±0.1% F.S.

- IP65

- Alloy Steel / Stainless Steel

- 150% of rated capacity

Static Torque Transducer Flange and Squre Drive Type Product Specifications

- Static reaction torque measurement using strain gauges

- Resistance Sensor

- Industrial & Research Grade

- Electroless Ni plated Tool Steel / Stainless Steel 17-4 PH

- 2 mV/V nominal Volt (V)

- 20 C to 80 C Celsius (oC)

- Measurement of static torque in shafts, actuators, motors, tools, and rotating machinery

- Input Resistance: 392 15 , Output Resistance: 350 3

- 10 NM - 50 KNM Kg

- Static Torque Transducer

- 10 VDC (Excitation Voltage) Volt (V)

- 10 C to 40 C Celsius (oC)

- 10 VDC (Maximum 15 VDC) Volt (v)

- 10 VDC Volt (v)

- Static Reaction Torque Transducer

- Actuator / valve / electrical tool testing Axle & shaft torsion testing Bearing friction measurement Testing of motors, pumps, engines, brakes, clutches Automobile drivetrain & crankshaft torque testing Defense, Aerospace, R&D labs, Offshore test rigs, Machine tools, Electrical & Engineering industries

- 0 C to 60 C Celsius (oC)

- Analog Sensor

- 0.5% FSO %

- Flange Mounted

- ±0.2% F.S.

- ±0.2% F.S.

- 10 Nm to 5000 Nm

- 2 meters (Standard)

- ±0.1% F.S.

- Flange & Square Drive

- ±0.1% F.S.

- IP65

- Alloy Steel / Stainless Steel

- 150% of rated capacity

Static Torque Transducer Flange and Squre Drive Type Trade Information

- VADODARA

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Number Per Week

- 1 Week

- Yes

- Asia, Australia, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Static Torque Transducer Flange and Square Drive Type

|

Model |

: | TTS-F-SQ | |

| Capacity | : | 0-2NM to 0-10 KNM | |

| Load Direction | : | Clock & Anti clock Wise | |

| Type | : | Torque Transducer / Torque Sensor Flange - Square Drive Type |

| Industries |

|

|

| Application |

|

|

| Description | : |

This is miniature torque sensor for statice torque measurements. |

| Features | : |

It is available from 2 NM to 50 KNM capacities. |

| Electronic Instrumentation / Software | : |

Suitable electronic instrumentation with software can be supplied as per customers requirements. |

| Mounting Hardware | : |

Required mounting hard wares can be suggested or supplied upon request. |

High-Precision Industrial Torque Measurement

This transducer is designed for static torque assessment in industrial setups, ensuring excellent accuracy and minimal drift. Its combination of flange and square drive compatibility allows seamless integration into diverse mechanisms. The robust construction and IP65 protection make it reliable for demanding environments, while the analog voltage output simplifies interfacing with standard monitoring equipment.

Versatile & Durable Construction

Configurable in alloy steel or stainless steel, the transducer withstands tough mechanical and environmental conditions. The flange mounting ensures stable installation, while the 2-meter cable grants arrangement versatility. Its broad rated capacity range (10 Nm5000 Nm) suits both light and heavy-duty applications, making it a universal solution for force measurement.

FAQs of Static Torque Transducer Flange and Squre Drive Type:

Q: How does the Static Torque Transducer determine torque values?

A: This transducer measures torque using strain gauge technology, which converts mechanical strain into a proportional analog voltage output. By reading the change in voltage, torque can be precisely calculated within the rated capacity.Q: What types of connections are available for integrating this transducer?

A: The device offers both flange and square drive types, making it compatible with various setups and mounting requirements in industrial or laboratory settings.Q: When should I choose stainless steel versus alloy steel construction?

A: Choose alloy steel for general industrial applications where cost-effectiveness is key. Opt for stainless steel when corrosion resistance is crucial, such as in chemical or marine environments.Q: Where can this transducer be installed?

A: Designed for static use, it can be flange mounted onto test benches, assembly machines, or torque calibration systems in manufacturing plants, R&D labs, or quality assurance stations.Q: What is the benefit of the 150% overload capacity?

A: The overload rating allows the transducer to safely handle torque loads up to 1.5 times its nominal capacity, protecting it from damage due to accidental overloading and extending its operational lifecycle.Q: How does the IP65 rating enhance device performance?

A: The IP65 rating ensures dust-tightness and resistance against water jets, allowing reliable operation in harsh or dusty environments without risking internal component damage.Q: What process should I follow to connect and operate the transducer?

A: Mount the transducer securely using the flange provided, connect to your monitoring equipment via the 2-meter standard cable, and excite it with a 10 VDC supply. Ensure the compatible output (2 mV/V nominal) is properly calibrated for precise analog readings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'REACTION AND ROTARY TORQUE TRANSDUCERS' category

|

ADI ARTECH TRANSDUCERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |