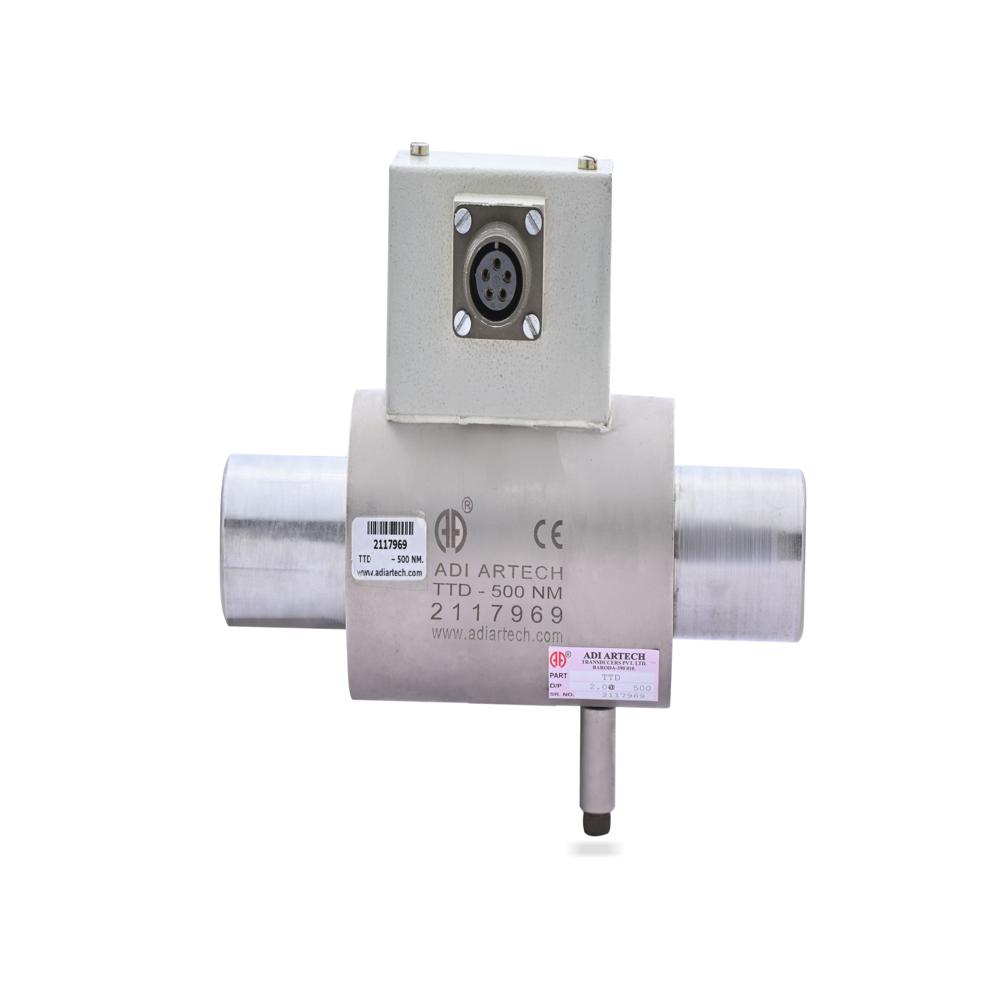

Torque Transducer with RPM measurement

120000.0 INR/Set

Product Details:

- Resistance 350

- Output Digital/Analog

- Theory Strain Gauge

- Type Rotary Torque Transducer with RPM

- Accuracy 0.1% F.S.

- Operating Voltage +12V to +24V DC

- Output Voltage 0-5V / 4-20mA

- Click to view more

X

Torque Transducer with RPM measurement Price And Quantity

- 120000.0 INR/Set

- 1 Set

- Flange / Foot Mount

- IP65

- 0-5000 RPM

- 0-100 Nm (other ranges available)

- Keyed Round Shaft

- 2 meters (customizable)

- Circular Multi-Pin

- Stainless Steel

- <1 ms

- 150% of Rated Torque

Torque Transducer with RPM measurement Product Specifications

- Strain Gauge

- 350

- 0.1% F.S.

- +20C 10C

- -20C to +80C

- Rotary Torque Transducer with RPM

- -10C to +60C

- Digital/Analog

- +12V to +24V DC

- 0-5V / 4-20mA

- Flange / Foot Mount

- IP65

- 0-5000 RPM

- 0-100 Nm (other ranges available)

- Keyed Round Shaft

- 2 meters (customizable)

- Circular Multi-Pin

- Stainless Steel

- <1 ms

- 150% of Rated Torque

Torque Transducer with RPM measurement Trade Information

- 10 Set Per Week

- 1 Week

- All India

Product Description

Torque Transducer with RPM measurement

|

Model |

: | TTD-SS-RPM | |

| Capacity | : | 0 - 50 NM to 0 - 50000 NM | |

| Load Direction | : | Clock & Anti clock Wise | |

| Type | : | Torque Sensor / Transducer - Shaft to Shaft - Dynamic with RPM sensor |

| Industries |

|

|||

| Application |

|

| Description | : | Shaft to Shaft Dynamic Slipring Torque Transducer is general purpose dual parametric sensor for accurate measurement of torque and RPM of rotating shaft or equipment. This sensor is fitted with RPM sensor to measure rotations of the machines. This is strain gage based sensor with full temperature compensation over 0 - 50 Deg.C. This is designed for compensation of unwanted axial and bending stresses. Torque sensing shaft is fitted with ball journals and electrical signals are transfered through high quality,low noise slip ring and brush mechanism. |

| Features | : | 0 - 50 NM to 0 - 50,000 NM range is offered. It is available for maximum 2500 RPM speed. Contact less radio telemetry transmitter type version is also offered for higher RPM. |

| Electronic Instrumentation / Software | : |

Stand alone digital display indicator for torque and RPM. |

Advanced Measurement Technology

Integrating strain gauge theory, the transducer delivers precise torque and RPM measurements suitable for various industrial sectors. Its digital and analog output options make data management straightforward, while overload resistance up to 150% of rated torque ensures durability in challenging environments.

Reliable Construction and Mounting

Manufactured with stainless steel and equipped with keyed round shafts, this device offers exceptional strength and stability. Flexible flange and foot mounting facilitate seamless integration into existing systems, ensuring secure operation even at high speeds.

Versatile and Customizable Features

Beyond its standard configurationincluding a 2-meter cablethe transducer can be customized to meet specific requirements. Its broad operating voltage range and selectable output signals enhance compatibility, making it a fit for varied industrial applications across India.

FAQs of Torque Transducer with RPM measurement:

Q: How does the rotary torque transducer measure both torque and RPM simultaneously?

A: This transducer employs strain gauge technology to measure torque and integrated sensors for RPM detection. The measured values are transmitted via digital or analog outputs, allowing users to monitor both parameters in real time.Q: What is the installation process for this torque transducer?

A: Installation involves mounting the device using either flange or foot options, connecting the circular multi-pin connector to power and data acquisition systems, and securing the keyed round shaft to your mechanical setup. The customizable cable length supports diverse installation environments.Q: Where can this torque transducer be utilized across industries in India?

A: It is suitable for applications in automotive, manufacturing, and research sectors, where accurate torque and speed measurement are essential. Its IP65 rating and wide temperature range allow operation in various environmental conditions.Q: What benefits does the fast response time of less than 1 ms offer?

A: A rapid response time ensures that dynamic changes in torque and speed are accurately captured, making the device ideal for processes where real-time monitoring and immediate feedback are critical.Q: When should the overload capacity feature of 150% be considered?

A: The overload capacity safeguards the transducer against unexpected torque spikes, which can occasionally occur during machine start-up or malfunction. Utilizing this feature ensures extended device longevity.Q: How is output data accessed and used in this device?

A: Output data can be accessed via either 05V or 420mA signals, enabling compatibility with most data logging, control, and diagnostic systems. This flexibility allows for seamless integration into new and existing setups.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'REACTION AND ROTARY TORQUE TRANSDUCERS' category

|

ADI ARTECH TRANSDUCERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |